Oct 13, 2025

What Are the Key Safety Steps to Operate an Industrial Paper Cutting Machine?

Sep 24, 2025

May 21, 2025

Mike Dooley

How to Navigate Critical Requirements & Discover Huayue's Specialized Solutions

While industrial paper cutters may appear straightforward in design, selecting the right machine for your operational needs—and ensuring its longevity—requires strategic evaluation. With 85+ years as "The Cutter People," we’ve guided countless businesses through this decision-making process, whether they ultimately purchase from us or not. Let’s simplify your journey through the complexities of modern cutting technology.

Guillotine-style cutters remain foundational to print shops worldwide, maintaining their core components (knife, clamp, table, backgauge) even as safety and precision evolve. Unlike rapidly advancing pre-press technologies, industrial cutters prioritize durability over frequent innovation—but this makes your selection process even more critical.

Five non-negotiable considerations now dominate purchasing decisions:

1. Material dimensions and handling requirements

2. Substrate composition and cutting resistance

3. Production volume and duty cycles

4. Service/support infrastructure

5. Compliance with modern safety standards

Overlooking any of these factors risks costly mismatches between equipment and workflow needs. Let’s examine the first three pillars of selection—with special attention to how Huayue Paper Cutters’ engineered solutions address complex cutting challenges.

While all Paper Cutting Machines have fixed maximum widths, true operational capacity demands deeper analysis:

Key Spatial Questions:

Can operators safely align materials against side guides?

Is there sufficient table space for multi-directional repositioning?

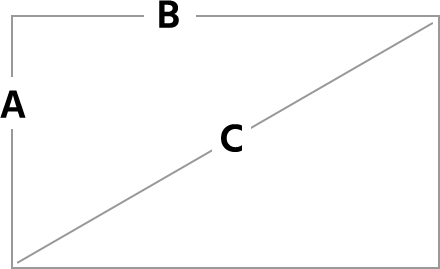

Does the machine accommodate diagonal measurements?

Sheets require cutter capacity exceeding their corner-to-corner diagonal measurement (calculated via A² + B² = C²). For example:

25" × 38" sheet = 45.75" diagonal

Trimmed to 25" × 37.5" = 45.07" diagonal

To meet the growing market demand for paper cutters, HPM offers solutions for high efficiency, large sheets, 210 mm cutting and front and rear loading. It can be flexibly adapted to different types of paper products.

Large Format Paper Solutions:

Standard with PDF, JDF cutting system and imported proportional valve, can undertake a variety of printed materials cutting production tasks with a high degree of automation, high production efficiency. Paper picker and unloader all adopt wave pressure lifting system and servo system with low noise, high precision, low maintenance cost and long service life.

210 Cut Height Paper Solutions:

210mm cutting height, so that cutting efficiency is greatly improved, the face of business card cutting and collocation printing paper products more comfortable. The paper picker and unloader all adopt wave pressure lifting system and servo system with low noise, high precision, low maintenance cost and long service life.

Efficiency Solutions:

Equipped with imported proportional valve, it is more flexible to face many types of paper products. Provide HPM-L, HPM-| and HPM-U solutions to meet individual need. Increase the output of individual paper cutter from 1 ton/hour to 4 tons/hour.

Outer wrapping paper solutions:

Work together, unloading paper while doing the rest of the work at the same time, for a more rational time schedule. For products with outer wrapping paper, our design helps you accomplish your production tasks efficiently.

While standard paper poses minimal challenges, modern operations increasingly confront:

Laminated boards

Composite materials

Plastic films

Multi-layer packaging substrates

Operational Reality Check:

24/7 operations demand industrial-grade components

Part-time usage (≤20 hrs/week) allows cost-effective reconditioned options

Need Immediate Guidance? Download our Industrial Cutter Selection Checklist or explore Huayue’s tailored solutions for complex cutting scenarios.

GET A QUOTE